Wholesale Weaving Yarn Ne 8/1 Cotton Yarn Open End Textile Combed Cotton Yarn

Various production processes of cotton yarn

* Open-end yarn

The task of the opening mechanism

1. Through the lifting and lowering movement of the heald frame, the warp yarns required for the full-width fabric are separated up and down to form a shed.

2. Control the order of lifting and lowering of the heald frame according to the order determined by the upper machine diagram, so that the fabric can obtain the required structure.

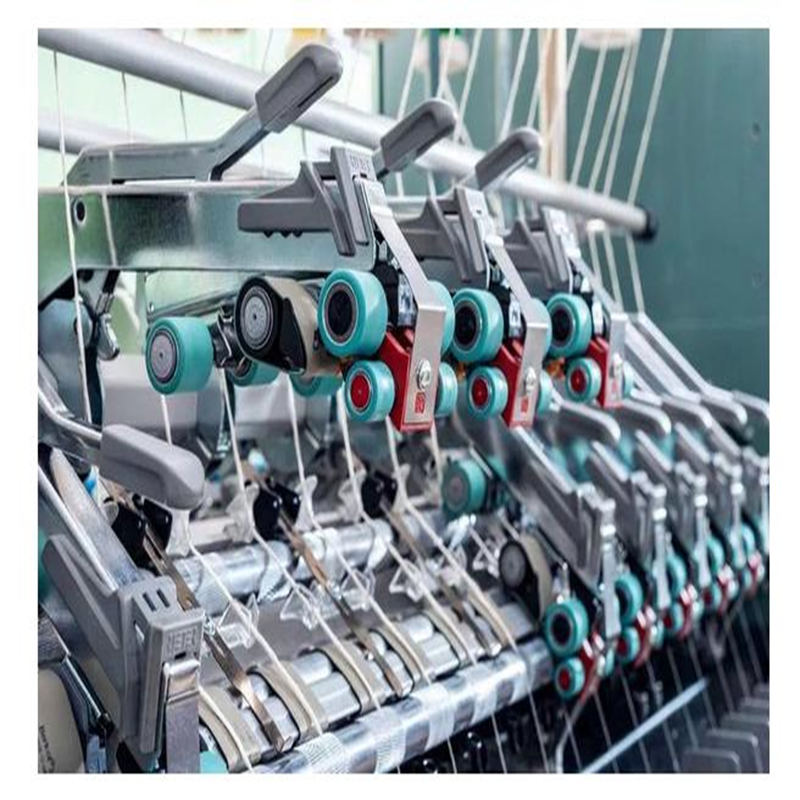

Air spinning is a new spinning technology that uses air to condense and twist fibers into yarn in a spinning cup with high speed rotation. No spindle, mainly by carding roller, spinning cup, twisting device and other components. The carding roller is used to grab and comb the cotton sliver fiber, which can be thrown out by the centrifugal force generated by his high speed rotation. The spinning cup is a small metal cup. It rotates 10 times faster than the carding roller. The resulting centrifugal action pushes the air out of the cup. According to the principle of fluid pressure, the cotton fiber into the airflow cup, and the formation of fiber flow, along the inner wall of the cup continuous movement

*Ring yarn

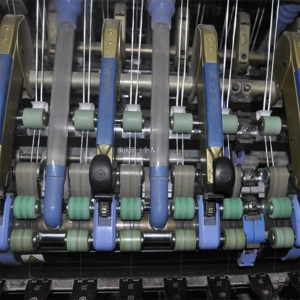

Ring spinning is a mechanical spinning method in which the spindles, steel collar and wire ring are twisted and drawn by rollers

* Compact yarn

A fiber agglomerating zone is added in front of the ring spinning frame traction unit, basically eliminating the spinning triangle zone between the front roller and the twisting point. Fiber after the article should be used to Laura before output, through the network eyelid circle, special-shaped suction duct coat must be a circle on the nose of the network movement, due to the effect of shrinkage and aggregation of the airflow, through abnormity tube suction slots make article must be gathered, rotation, gradually from flat belt into the cylinder, the end of the fiber were twisted into yarn, the yarn is a tight, yarn appearance bright and clean, less hairiness. Compact yarn has higher strength and less hairiness

* Siro yarn

Siro spinning is to feed two roving yarns at a certain distance on the spinning frame. After drawing, the front roller outputs the two single yarns with a small amount of twist on the single yarns due to the transfer of twist. After assembling, the single yarns are further twisted into a similar yarn, which is wound on the bobbin

* Compact Siro yarn

Siro compact spinning combines the advantages of siro spinning and compact spinning. Siro compact spinning has very good CV value, coarse knot and detail index, high single yarn strength, compact structure, good wear resistance, less hairiness, few harmful hairiness over 3mm, smooth yarn and high fabric quality

Features of cotton yarn

Pure cotton yarns are widely used in clothing and home textiles, and can be used for almost any textile needs, because now all man-made fibers and synthetic fibers are used to replace cotton.

At present cotton yarn in the clothing field according to the scope of use there are mainly several categories: denim, dyed cloth, yarn-dyed cloth, according to the way of weaving can be divided into: knitting and tatting and non-woven cloth.

Pure cotton yarns are mainly used in the field of jeans with low air spinning yarns, which require good strength, coarse yarn and rough cloth style.

In the field of dyeing, pure cotton yarns are divided into garment fabrics and home textile fabrics. In the field of clothing, yarns are widely used, applicable products are available for 7s-100s and even 200S. Trousers fabrics mainly use yarns of 7-30s. For coats, there are a wide range of yarns. For shirts, high-count yarns are mainly used, such as 32S-60S single yarns or 60/2,80/2,100/2 or even higher strands.

Home textile fabrics are generally 32s 40s 60s 80s, of course, other yarns are also used

The advantage of pure cotton products lies in that pure cotton is taken from nature and is one of the most primitive fibers (cotton, hemp, silk, wool). It has been used since ancient times. Cotton fiber is skin-friendly, and there is basically no allergic population. Qiu dong season can do cotton fabric to grind wool processing, reduce the cool feeling of cloth face.

Cotton has better thermal performance under dry conditions, but basically no thermal performance under wet conditions