Storm muti-flow high temperature dyeing machine

Product Advantages

1. Full-mode model

Can switch freely between air atomization airflow and overflow dyeing. This model is suitable for both tightly woven fabrics and normal knit fabrics. It gathers the advantages of air atomization, airflow and overflow dyeing. The dyeing process mode can be set according to different fabrics. This widens the machine application range greatly, improves dyeing performance and greatly saves the power consumption.

2. Patented design

Patented direct-link blower with double air vent greatly increases wind pressure. Meanwhile, the minimum power of single tube is 3.5 kw only. The energy consumption is much lower than other similar airflow dyeing machines in the market. The blower will be closed for pure overflow dyeing mode.

3. High Quality Dyeing

Widely used for dyeing easy crease fabrics such as 19s tightly woven cotton fabrics, high twist high density veil fabrics, high twist double layer fabrics, thick fleece and NR Ponte-de-roma. It can also dye woven fabrics like P/C, N/C,T/C, spandex and faille which are rather difficult for low ratio overflow dyeing machines.

STORM even has good performance in synthetic fiber woven fabrics such as chiffon, memory fabric, pongee, polyester taffeta, nylon taffeta and etc.

4. Super Large Capacity

Max. Capacity of each tube: 350kg

Max. Capacity of the dyeing machine: 2800kg

5. Highly Intelligent Control

The standard configurations include:

Flow meter for water supply control; Automatic filtering system; Seam detecting system; Proportional heating and cooling system; Dynamic drainage and etc.

Ultra Low Energy Consumption

The blower energy consumption is 3.5kw/tube, close to that of overflow dyeing machine. Meanwhile, the machine saves water similar as airflow dyeing machine.

| Cotton with reactive dyes | Woven with reactive dyes | |

| Water | Approx.40 ton/ton fabric (dark color) | Approx.25 ton/ton fabric (dark color) |

| Power | Approx. 150 ton/ton fabric | Approx. 100 ton/ton fabric |

| Steam | Approx. 1.6 ton/ton fabric | Approx. 1.5 ton/ton fabric |

| Auxiliaries | 40% can be saved | 40% can be saved |

6. Pure overflow function (option)

Pure overflow mode: three optional modes on 1 machine atomization, airflow and overflow. Pure overflow mode can be set according to customer's requirement.

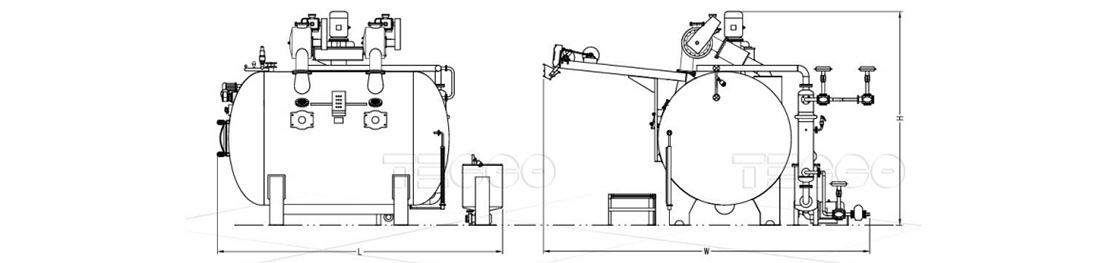

Structure Chart

Air flow dyeing machine

MODEL

| Model 3 type | No. of tubes | Capacity kg | Total power (kw) | Dimensions (L*W*H)mm | ||

| QD3-S50HT | 1 | 50 | 20 | 2600 | 4300 | 3390 |

| QD3-S100HT | 1 | 100 | 20 | 3000 | 4300 | 3390 |

| QD3-S150HT | 1 | 150 | 22 | 3200 | 4600 | 3500 |

| QD3-1HT | 1 | 300 | 28 | 3900 | 5780 | 3840 |

| QD3-2HT | 2 | 600 | 38 | 5160 | 5980 | 3870 |

| QD3-4HT | 4 | 1200 | 67 | 8380 | 6000 | 3870 |

| QD3-6HT | 6 | 1800 | 98 | 11750 | 6000 | 4000 |

| QD3-8HT | 8 | 2400 | 127 | 13950 | 6500 | 4010 |

High gram fabric dyeing machine

MULTI-FLOW high temperture dyeing machine

Ultra low ennegy consumption dyeing machine