Products

-

Cotton yarn

Various production processes of cotton yarn * Open-end yarn Air spinning is a new spinning technology that uses air to condense and twist fibers into yarn in a spinning cup with high speed rotation. No spindle, mainly by carding roller, spinning cup, twisting device and other components. The carding roller is used to grab and comb the cotton sliver fiber, which can be thrown out by the centrifugal force generated by his high speed rotation. The spinning cup is a small metal cup. It rotates... -

Hemp yarn

Breathable, with a unique cool feeling, sweat does not stick to the body; Bright color, good natural luster, not easy to fade, not easy to shrink; Thermal conductivity, hygroscopic than cotton fabric, acid and alkali reaction is not sensitive, anti mold, not easy to be damp mildew, moth resistance, hemp fabric can adjust the temperature, but also anti-allergy, in winter can be anti-static, and especially suitable for patients can pass, can have the effect of resistance, and sui... -

Lyocell yarn

Lyocell Yarn Lyocell is a new kind of natural regenerated cellulose in the refining and wood pulp, with natural polymers as raw material, return to nature, absolutely pure, known as the 21st century, green environmental protection fiber, merge the advantages of the silky texture, viscose has a trailer with elegant and rich and dynamic, soft tactility, well ventilated smooth and easy maintenance, the fabric has good cool feeling, Hygroscopic and natural drooping Lyocell fiber, c... -

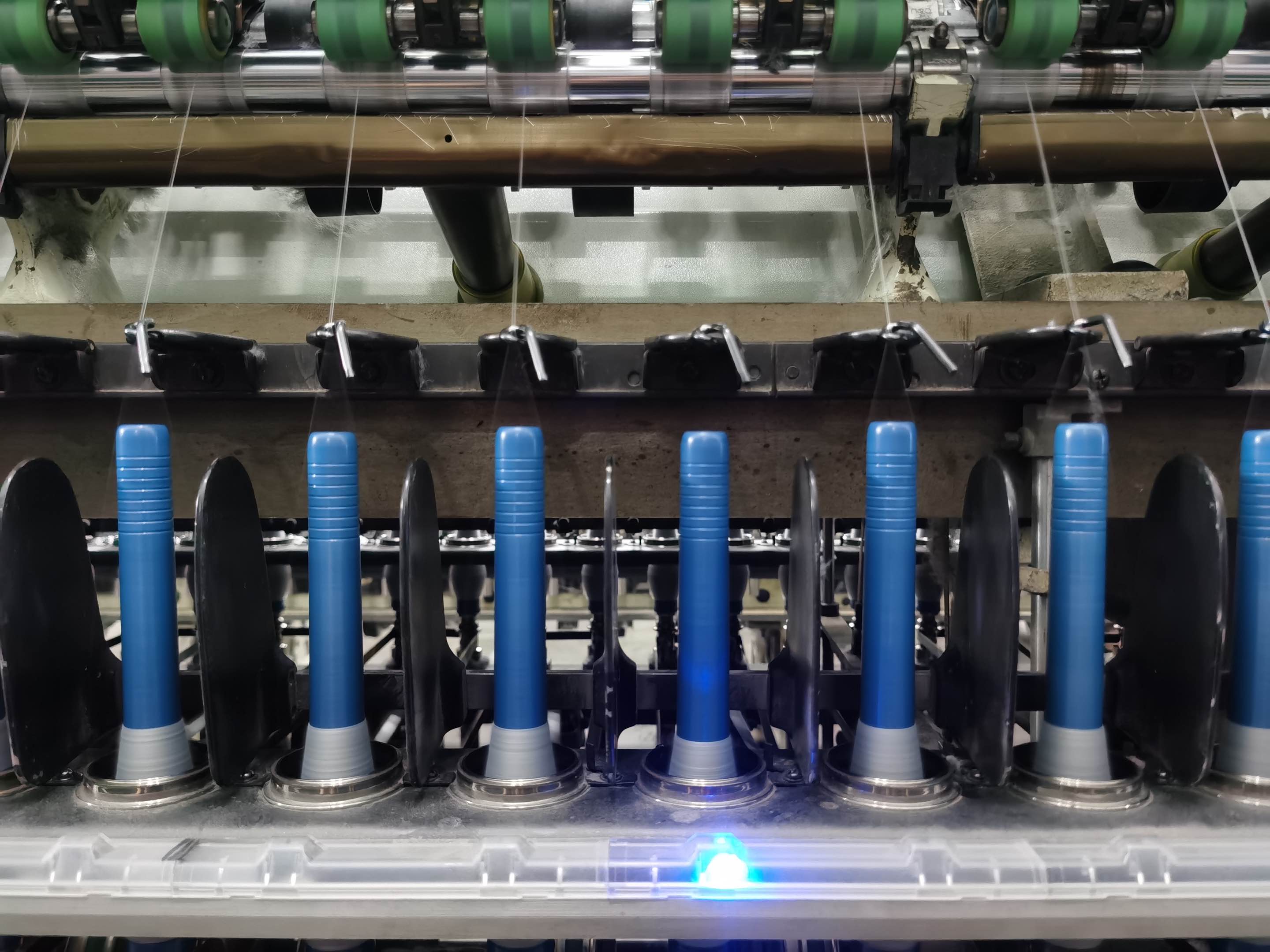

compact spinning transformation

high quality compact device, can efficient reduce yarn hairness and increase yarn quality, can widely use in all kind of spinning frame models

-

RING SPINNING YARN DETECTION SYSTEM

1、 Reduce useless patrolling,improve working efficiency,reduce labor intensity.

2、 Reduce roving waste and recycle rate.

3、 Reduce roller winding and reduce equipment consumption.

4、 Reduce empty spinning spindles and improve machine output.

5、Reduce weak twist spindles and ensure yarn strength.

6、 Reduce fluff pollution and yarn breaking hairiness.

-

Viscose

Lyocell Yarn viscose Viscose refers to viscose fiber, viscose fiber is the natural wood, reed, cotton short velvet and other cellulose as raw material, made by chemical processing, divided into filament and short fiber two kinds. Filament is also called rayon or viscose silk; Staple fibers are cotton (also known as artificial cotton), wool (known as artificial wool) and medium and long fibers. Rayon commonly known as cotton staple fiber. The main varieties of cellulose or protein an... -

spinning frame function transformation

All kinds of functional transformation for spinning frame, collective doffing function, slub function, core yarn function, fancy yarn function, super flexible yarn function and full electronic control head transformation

-

-

Pineapple winding machine

QD011 type digital winding machine can be used for processing all kinds of yarn, such as spun and filament ,the winding speed up to 1200m/min, the precision of servo control system, the on-line tension technology , and in the procedural control to a computer terminal on all process parameter, Advanced technology and innovative solutions to ensure the machine can be the best way to control the yarn of compart array, high reliability, high efficiency , versatility , and commonality of the most widely applicability.

-

Soft & hard cone winding machine

This machine for compact yarn production cone type, for needle loom, weaving machine, warping machine, hosiery machine use The winding speed of the machine can be controlled automatically through the computer, up to 1100m/min. the control of radial anti-aliasing device is convenient. Advance yarn clearing and tension mechanism with photoelectric yarn to avoid yarn winding. The precision and sensitivity of the device can be used to ensure that the length (weight) of the winding is uniform. Electric rotating waxing device can meet the needs of the yarn and the uniformity of the amount of max. It’s the perfect machine for rewinding, separate tube yarn (cotton, hemp, silk and chemical fiber yarn).

-

Denim garment dyeing and washing

Technology parameters: Special-designed drum for low liquor ratio Description for the machine 1. Specially for industrial garment washing & dyeing like jeans, sweaters and silk materials. 2. Special designed drum for low liquid ratio. 3. Direct & indirect heating are available. 4. Door safety switch for safe operation. 5. High quality inverter control. Options: 1. PLC touch screen system 2. Digital control panel 3. Automatic water inlet draining steam inlet function. 4. Pne... -

Denim garments surface treatment eqipment

1.BOX TYPE DENIM CURING OVEN FOR JEANS CRUMPLED AND SETTING Description for curing oven Global advanced technology of industrial oven. Heating in a short time, max temperature can be in 200 centigrade and the Temperature difference is small. This kind of oven is mainly used for jeans finalizing Features for curing oven: 1. Box design with high quality cotton insulation which ensure the heat be used perfectly. 2. Quickly heat cycling helps to save the energy. 3. Controlling by every clea...