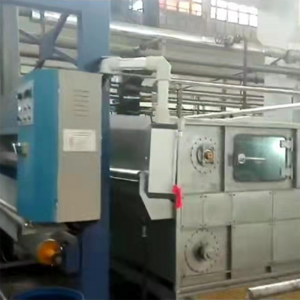

Precision blanket pre-shrinking machine

Product use range

The product is used for sizing and shrink-proof finishing of pure cotton, blended cotton and chemical fiber cylindrical knitted fabrics.

Features: adopt magnetic suspension electric separating shuttle plate, control fabric width precision ±5mm, no extrusive printing, plate belt feed cloth to eliminate weft slant.

Electric amplitude, easy to operate.

The 20mm thickened woolen blanket and the teflon film to realize damping and anti-shrinkage, and the longitudinal shrinkage rate can reach 3% .

There is a hole detector at the cloth entrance end, and the hole at the cloth edge will stop automatically.

Fault automatic display, convenient for maintenance.

Stainless steel steam box with double nozzles, high moisture content, even moisture content.

Electric heat transfer oil dryer, uniform temperature, automatic control, free setting, the highest temperature can reach 220 ° C.

Variable frequency speed regulation.

With the rising force adjusting roller, the fabric rising force is automatically adjusted.

Suction cooling when fabric out,fabric size stable.

Precision Laminate.

PLC + touch screen industrial control system and width on-line detection system can be configured according to user's needs.

Operating width: 1400mm

Electrical heating power: 33Kw (48KW)

Heating mode: electrical heating, heat conducting oil heating, steam heating

Mechanical speed: 0-30m/min

Roller diameter: Φ400, Φ500

Motor capacity: 12Kw dryer

Operating temperature: 0-220 ° C (0-150 ° C)

External size -(length × width × height) : 5910 × 2650 × 2400mm

Whole machine weight: 5 tons