OEM/ODM Manufacturer Dying Painting Machine - Automatic sealing and cutting heat shrink packing machine – Singularity

OEM/ODM Manufacturer Dying Painting Machine - Automatic sealing and cutting heat shrink packing machine – Singularity Detail:

Equipment List

1.1 set of automatic edge sealing, cutting and packing machine (customization)

2. 1 set of internal circulation thermostatic shrink packaging machine (customization)

3. 1 pcs of no power roller line.

Main performance characteristics

1.QD-10035TBC is automatic unmanned operation of economic edge sealing packaging machine, widely used in mass production of packaging flow, automatic feeding, conveying, bag, sealing, shrink completed at a time, high efficiency, suitable for different height and width of products.

2. Sealing part of the transverse knife using vertical drive, longitudinal knife using constant temperature side sealing knife, sealing line straight and firm, can ensure that the sealing tangent line in the middle of the product, to achieve sealing effect.

3. Using constant temperature heating sealing and cutting system can be used to seal and cut POF and other industrial standard shrinkage film. Products with different packaging specifications and sizes can be adjusted by hand wheel, which increases reliability and makes it easier to operate.

4. The longitudinal sealing knife can do the sealing and cutting action sustainably, the length of the product is not limited.

5. The machine adopts PLC programmable controller, with safety protection and alarm device, and sealing and cutting system can continue to make smooth sealing action, no replacement, maintenance operation is very simple.

6. Feeding length control by combination of electric eye detection and timer, accurately control the length of film, so that the shrink effect is easy to control.

7. Add two groups of horizontal and vertical electric eyes, easy to convert selection, for thin or small packaging, can easily finish the sealing and packaging operation.

8. Automatic take-up waste material, using a separate motor control, will not be too loose or too tight and crack, waste materials easy to disassemble.

9. Using 304 stainless steel heating tube, long service life, simple appearance, reasonable structure, convenient maintenance and operation.

10. Lengthen shrinkage area, good heat insulation effect, temperature controller and thermal sensing precision control temperature.

11. Adopt Taiwan brand motor to control conveying to ensure stable conveying operation.

12. Shrinkage furnace air transport system adopts spiral inner circulation air transport, less heat loss, good product shrink effect.

Technical parameter

Technical parameter of automatic edge sealing, cutting and packing machine:

|

Model |

QD-8050TBC |

|

Max. packing length |

Unlimited length |

|

Max. packing width + height |

≤850mm (For example: fabric height 350mm. then the fabric width ≤500mm) |

|

Max. packing height |

≤350mm |

|

Length of horizontal sealing knife |

1000mm |

|

Speed of conveyor belt |

0-15m/min |

|

Power source |

220V/380V 50HZ 3 phase |

|

Packaging speed |

Depending on the package size (0-25 PCS/min) |

|

Air source |

≥ 6-8kg/㎡ |

|

Power |

3kw |

|

Working table height |

800mm±50mm |

|

Machine weight |

980KG |

|

Applicable shrink film |

POF shrink film |

|

Machine size |

2430*1565*1400mm |

Technical parameter of internal circulation thermostatic shrink packaging machine:

|

The furnace chamber temperature |

Room temperature -200° adjustable |

|

Conveyor belt speed |

0-10m/min |

|

Conveyor loading |

≤40KG |

|

Power |

44kw |

|

Power source |

380V 50HZ 3 phase |

|

Working table height |

850mm±50mm |

|

Applicable shrink film |

POF shrink film |

|

Machine weight |

850kg |

|

Furnace chamber size |

2500*800*500mm |

|

Machine size |

2800*1100*1750mm |

Automatic sealing

Automatic sealing, cutting and packing machine configuration list:

|

Name |

Parameter |

|

The heat source |

Stainless steel heating tube, long service life |

|

Sealing knife |

Using anti-stick high temperature alloy sealing knife, knife plating Teflon membrane |

|

Temperature control of sealing knife |

Adopt Japanese “OMRON” digital display temperature controller and thermal induction control, temperature 0-300℃adjustable |

|

Sealing cutter size |

Adjustable width manual runner, height 10-350mm; Sealing cutter size: 1000mm Length |

|

Sealing knife protection |

Adopt the German “SICK”, effectively prevent packaging objects by mistake |

|

Conveyor belt |

SIEGLING PU |

|

Conveying system motor |

OKG |

|

Conveying system detection |

American “Banner” photoelectric sensor, accurate and sensitive detection of product delivery and stop |

|

Recovery system motor |

“OKG” ensures accurate and uniform recycling of waste |

|

Induction switch of recovery system |

Adopt Japanese “Omron” accurately control film feeding quantity |

|

Film feeding system motor |

“OKG” |

|

Induction switch of film feeding system |

OMRON |

|

PLC |

FATEK Taiwan/OMRON |

|

Switch |

SCHNEIDER |

|

Intermediate relay |

OMRON |

|

Thermostat |

OMRON |

|

Emergency switch |

SIEMENS |

|

Mechanism material |

Carbon steel plastic spraying, the key parts are made of stainless steel plate and aluminum profile, make sure the structure is firmed |

Internal circulation thermostatic shrink packaging machine configuration list:

|

Name |

Parameter |

|

High Temperature Wire |

Industrial grade special high temperature line with temperature resistance of 700° is suitable for long time operation of equipment |

|

Contactor |

CHINT |

|

Button switch |

CHINT |

|

Delay shutdown control system |

Adopt South Korea ” AUTONISIC ” brand |

|

Emergency stop |

CHINT |

|

The heat source |

Stainless steel heating tube, long service life, heating tube distribution in the furnace chamber |

|

Thermal insulation layer |

Using high temperature resistant aluminum silicate material to make insulation layer thickness of 50-80mm, to ensure the heat to reduce electricity consumption |

|

The temperature control |

Adopt Korean ” AUTONISIC ” temperature controller and thermal sensor, temperature 0-200℃. |

|

Conveying system motor |

Taiwan “DONGYUAN” brand motor, reducer |

|

Conveying system inverter |

DELTA |

|

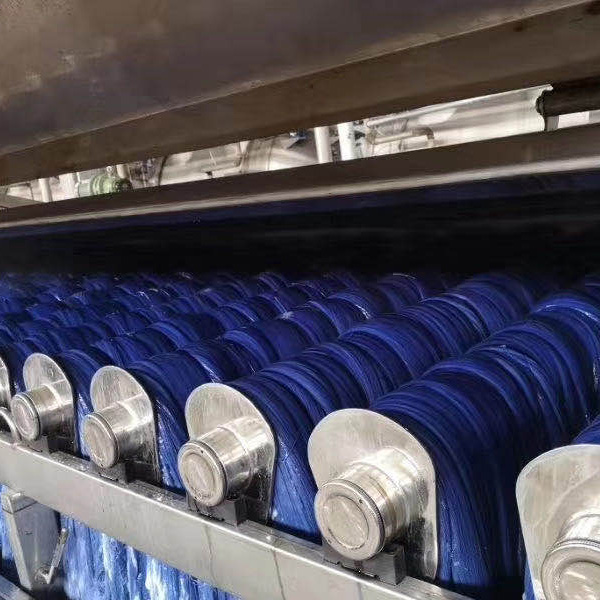

Conveyor roller |

Adopt φ10mm solid chain rod type conveying, coat thickness 2mm silicone tube or high temperature tube. |

|

Conveyor chain |

Extended pin high temperature chain, durable-service. |

|

Carrying the wind system |

Adopting hot air inner circulation technology, several high-power air transporting motor and preset air transporting channel, Make the furnace to produce uniform thermal circulation wind, the shrink effect is ideal and reduce heat loss. |

|

Motor of the wind system |

ESPA brand high temperature motor |

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for OEM/ODM Manufacturer Dying Painting Machine - Automatic sealing and cutting heat shrink packing machine – Singularity , The product will supply to all over the world, such as: Mexico, Namibia, Brisbane, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.