Newly Arrival Jigger Machine In Textile - Heavy-duty warehouse rack – Singularity

Newly Arrival Jigger Machine In Textile - Heavy-duty warehouse rack – Singularity Detail:

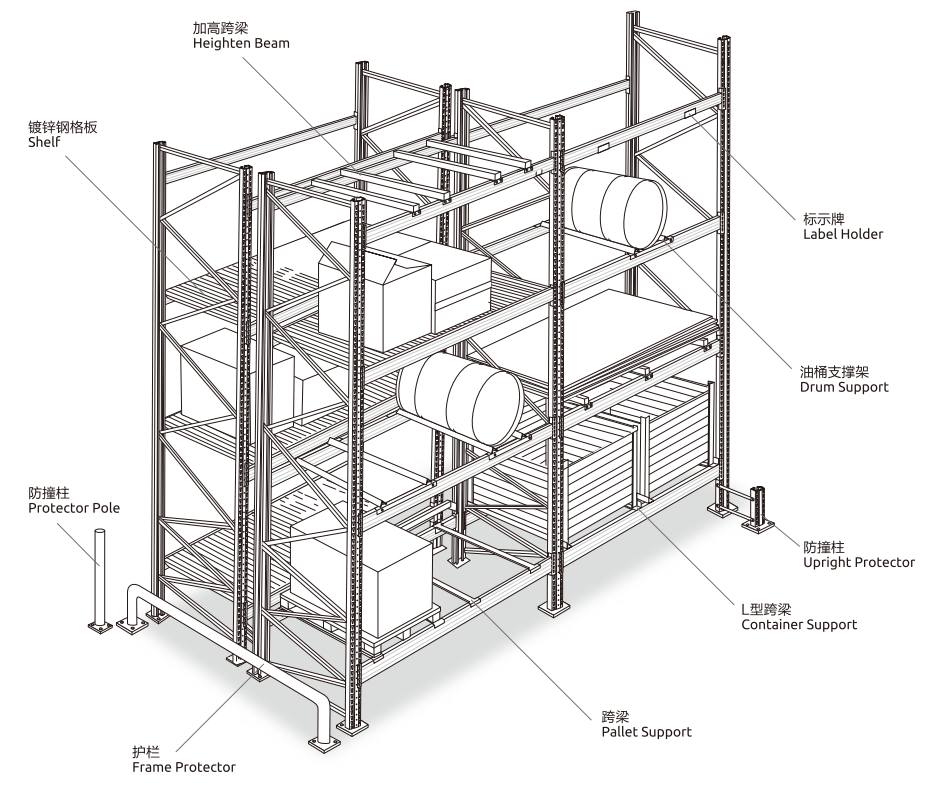

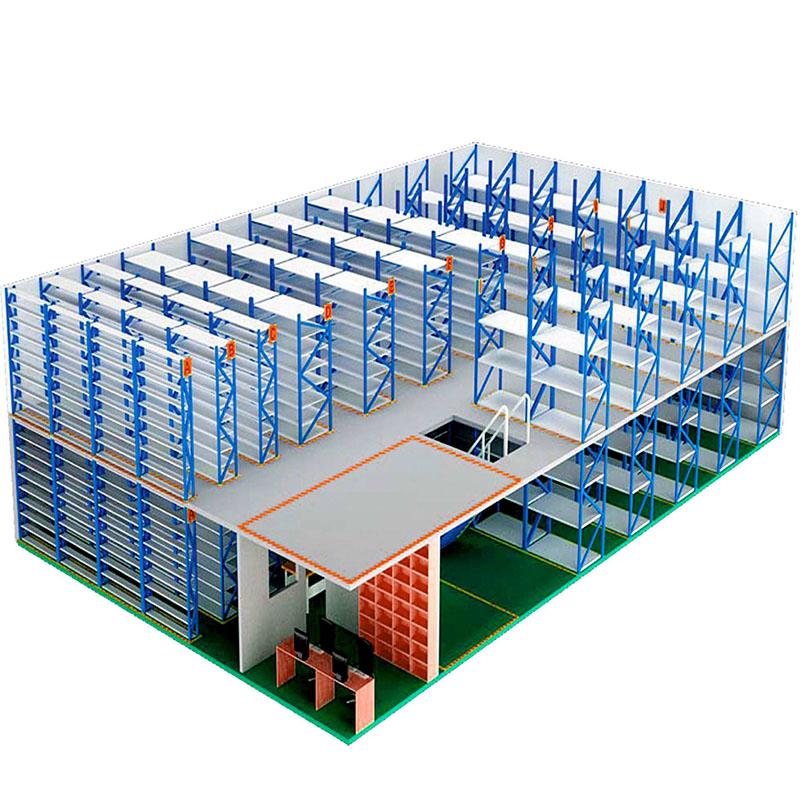

PALLET RACKING

Pallet racking is commonly used for storage of items packed with pallets, picked or loaded with forklift. Pallet racking has low storage density but high picking efficiency & low costs

Product Features

* 100% picking efficiency

* Easy for handling equipment

* Adjustable beams for different cargoes

* Varieties of upright and beam size for the most economic structure

The main characteristics

1, usually goods through the pallet, storage cage and other units assembled equipment after the storage shelf storage. Each unit load is generally less than 4000kg, each layer usually put two units.

2, Heavy duty rack is one of the most common and widely used shelves, suitable for the vast majority of warehouses or product goods.

3, with 100% arbitrary picking characteristics of goods. Handling machinery such as forklifts can reach any cargo space for storage operations, storage operations convenient, fast!

4, with mechanical handling equipment for storage operations.

5, unit shelf span is generally within 4m, depth within 1.5m, low and high warehouse shelf height is generally within 12m, ultra high warehouse shelf height is generally within 30m (such warehouses are basically automated warehouses, shelf height is composed of several columns within 12m).

6, can be 75mm integer multiple freely adjust the height of each layer.

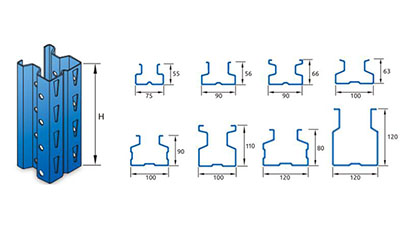

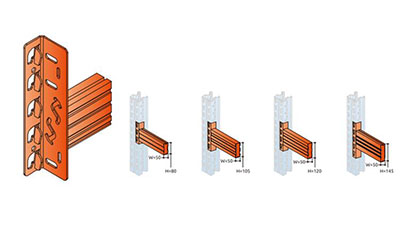

Heavy duty (beam type) shelves are generally made of cold rolled special-shaped steel. The column is made of 80(90) X60 (70) ω steel surface with diamond holes, and the beam is made of 80×50-100×50-120×50-140×50-160×50 welded beam connecting pendents. Pallet is generally used instead of layer plate to facilitate forklift handling. Layer load of 1 ton to 5 tons of design, surface electrostatic spray, waterproof, rust and corrosion prevention ability is stronger, high safety factor, plug type combination, do not need to use screws and welding, assembly is very convenient, make full use of space area, provide storage capacity.

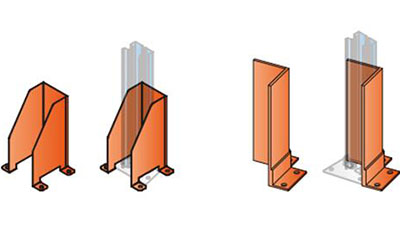

Structure

Heavy shelves by column, beam, cross brace, diagonal brace and self-locking bolt assembly, can effectively prevent the bolt loose after causing shelf instability; The beam adopts special cold rolled P-type closed beam; The structure has the characteristics of simple and reliable, light weight, strong bearing capacity and low cost. When the column card is connected with the column, it is equipped with a specially designed safety pin, which can ensure that the beam will not fall off under the impact of external force. Laminate is made of strip laminate in the world, which has the characteristics of strong bearing capacity, wear resistance, simple replacement and low maintenance cost

Installation method

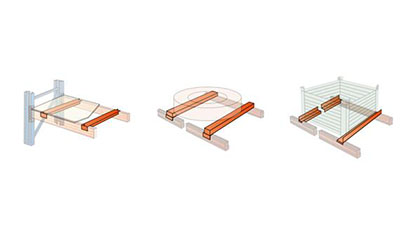

First the horizontal pull (horizontal support), diagonal pull (diagonal support) with screws installed on the column. The assembled two column pieces (one column piece = two columns + several horizontal pull + several diagonal pull) erected on the ground two column pieces to adjust the distance to the length of the beam can be installed on the beam.

When installing the auxiliary frame, it is also necessary to install the column pieces first, and then adjust the distance from the column pieces to the length of the beam after installing the beam

Advantage

1, fully assembled structure, optional combination, convenient installation, disassembly and flexibility.

2. The column is made of hot rolled plate folded into multiple angles, so the load bearing capacity of the shelf is large.

3, column for assembled structure, steel buckle card connection between beam and column, and set a safety key lock, prevent falling off.

4, the column is equipped with 75mm adjustment hole distance, can be adjusted according to the height of the goods.

5, suitable for stacking height storage of materials, can make full use of the space of the warehouse to achieve the purpose of material classification management, can be used with forklift or stacker

Process

Degreasing-washing-pickling derusting- washing-oxalic acid neutralization- washing-phosphating- washing- hot air drying- coating and paint drying Paint-drying thickness over 60microns.

|

Upright |

|

|

Beam |

|

|

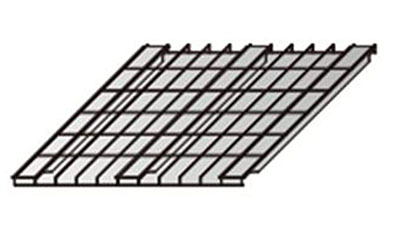

Cross beam |

|

|

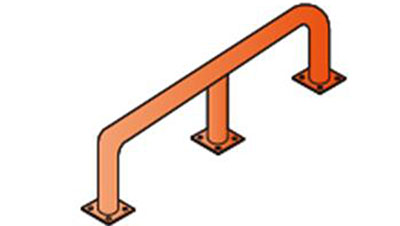

Upright Protector |

|

|

Frame protector |

|

|

Mess plate |

|

Product detail pictures:

Related Product Guide:

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Newly Arrival Jigger Machine In Textile - Heavy-duty warehouse rack – Singularity , The product will supply to all over the world, such as: Curacao, Ecuador, Angola, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.