Discountable price Dyeing Process - Indigo Slasher Dyeing Range – Singularity

Discountable price Dyeing Process - Indigo Slasher Dyeing Range – Singularity Detail:

Specifications

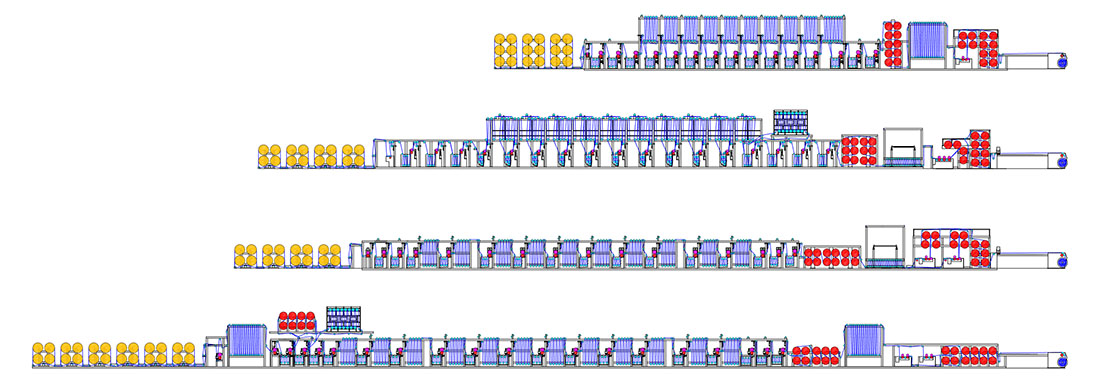

| 1 | Machine Speed (Dyeing) | 6 ~ 36 M/min |

| 2 | Machine Speed (Sizing) | 1 ~ 50 M/min |

| 3 | Airing Length | 32 M (Typical) |

| 4 | Accumulator Capacity | 100 ~ 140 M |

Beam Creels

Features

| 1 | Dyeing + Sizing |

| 2 | Efficient Production |

| 3 | Minimum Yarn Breakage |

| 4 | Multiple Production Modes |

| 5 | Highly Automated Production |

Beam brake

Electric Cabinet Partial View

Principles for slasher indigo dyeing

1. Yarn is first prepared (by ball warping machine for rope dyeing, by direct warping machine for slasher dyeing) and start from the beam creels.

2. Pre-treatment boxes prepare (by cleaning & wetting) the yarn for dyeing.

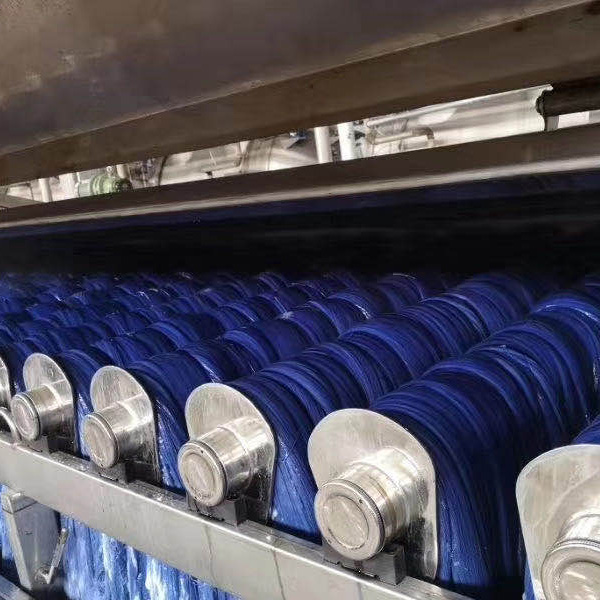

3. Dye boxes dye the yarn with indigo (or other types of dye, such as sulfur).

4. Indigo is reduced (as opposed to oxidation) and dissolved in the dye bath in the form of leuco-indigo in an alkalic environment, with hydrosulfite being the reduction agent.

5. Leuco-indigo bonds with yarn in the dye bath, and then brought into contact with oxygen on the airing frame, leuco-indigo reacts with oxygen (oxidation) and turns blue.

6. Repeated dipping and airing processes allow indigo to gradually develop into a darker shade.

7. Post-wash boxes remove the excessive chemicals on the yarn, additional chemical agents may also be used at this stage for different purposes.

8. sizing process is done right after dyeing on the same machine, final beams are ready for weaving.

9. Productivity-wise, a slasher dyeing range usually has about HALF the production capacity of 24 / 28 ropes dyeing range.

10. Production capacity: About 30000 meters yarn by a slasher dyeing range.

Headstock

Sizing box

Split zone

Top View of slasher dyeing machine

Automatic Tension Control

Endress+Hauser Flowmeter

Top sheet & Bottom sheet

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Discountable price Dyeing Process - Indigo Slasher Dyeing Range – Singularity , The product will supply to all over the world, such as: Hamburg, Romania, Qatar, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.